We aim to be the preferred choice when it comes to quality, reliability, innovation and dedication.

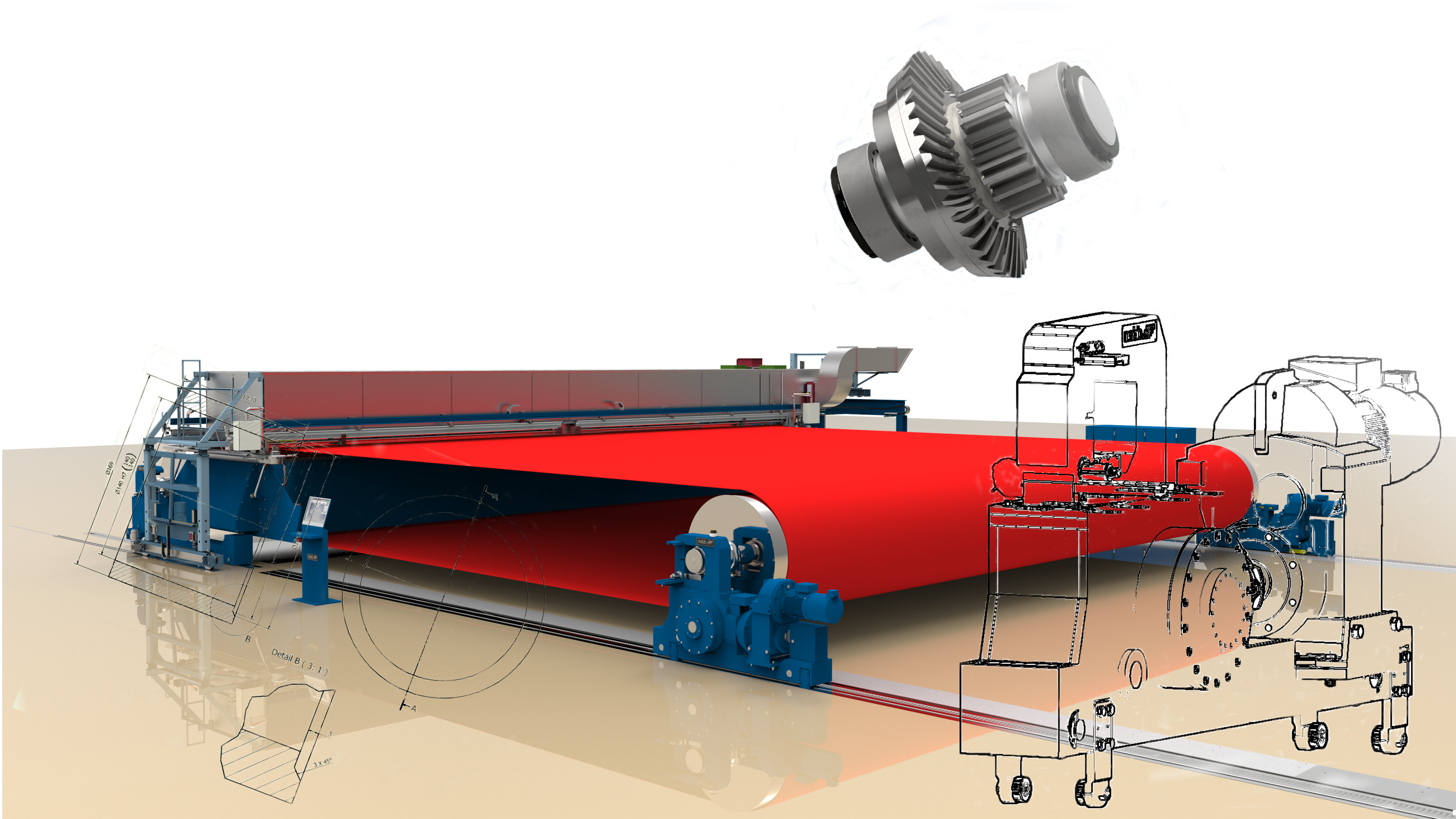

Nebb's Finishing Machines are modern high-quality heatsetting machines, heavily invested in.

Together with the former Kvaerner and Thune companies, we have supplied finishing machines and related services to the PMC market worldwide for 40 years. We have afterwards continued and expanded the activities within this market.

Based on our experience delivering nearly 100 finishing machines, we are able to offer complete machines which meet modern requirements in production quality, efficiency, and economy.

Instead of the manually performed trimming and sealing of fabric edges while the product is still on the finishing machine, we have developed an automatic edge trimming device which simplifies this time-consuming process. It also eliminates the risk of a personal injury, and increases the production capacity.

The NebbPerm measuring gauge can be a hand-held unit or carriage-mounted on a high precision linear rail, allowing controlled positioning for fixed- or cross-machine measurements, as preferred. The rail can be mounted on the cantilever beam or on another suitable location on the machine.

The operator interface can run through existing HMI software, or through a separate PC. Customer-specific reports can be generated at request.

When operating a finishing machine, personnel can be exposed to hazardous situations. Working close to large rolls rotating with high inertia demands extra caution. Official safety regulations require the installation of systems to minimize operator injuries. Nebb have developed a disc braking system to stop rotation as quickly as possible in emergency situations.

The core activity is completing and optimization of machine systems from scratch, carefully following the conceptual design at an early stage.

Our Engineers' knowledge and experience in use of various CAD and CAE tools is incorporated throughout the product life cycle

Increased product inventiveness, reduced released time of the product on the market, hence reducing the production expenses in general.

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Nebb provide total solutions for automation, electrical and information systems to a number of industries world-wide, including process industry, food & pharma, marine, energy, subsea, and PMC.

Our core competence lies within automation, electrical, instrumentation, SCADA, software, and digitalisation.

[fa icon="phone"] +47 66908300

[fa icon="envelope"] sales@nebb.com

[fa icon="envelope"] general@nebb.com

[fa icon="home"] Solbråveien 43, Asker Norway