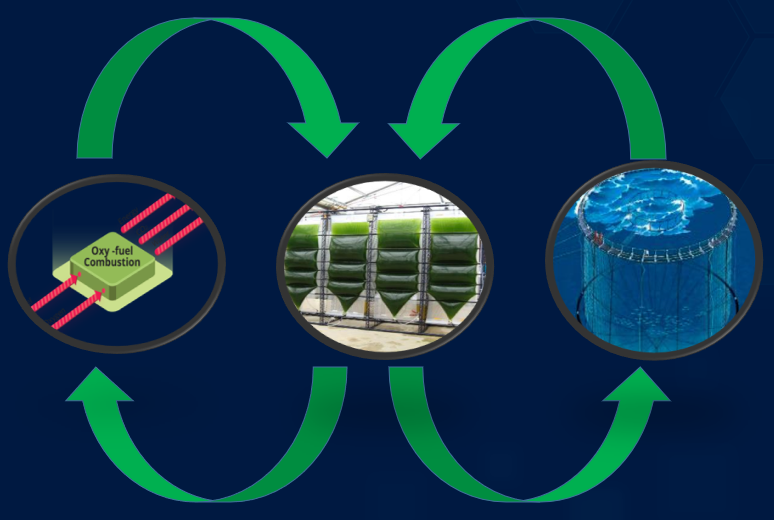

Marine Cluster combines Oxy-fuel energy plants and algae production to get a unique solution that utilizes "by-products" from both processes to very valuable additives in each other's operations, allowing for the efficient use of resources.

In line with many of the UN Sustainability Goals, this opportunity enables a green shift with emission-free value creation.

Most climate scientists agree that the climate on earth is about to change due to human greenhouse gas emissions. Today 35% of global CO2 emissions come from power and heat production. For almost two decades, Nebb has been working on CO2-free gas power plants to reduce some of the world's emissions.

We completed a concept study for a pilot and demonstration plant with zero emissions for ZENG AS in 2007, collaborating with the project sponsors Gassnova, Statoil ASA, Shell Technology Norway AS, and Lyse Energy AS. Through this work, Nebb identified a unique opportunity for circularity.

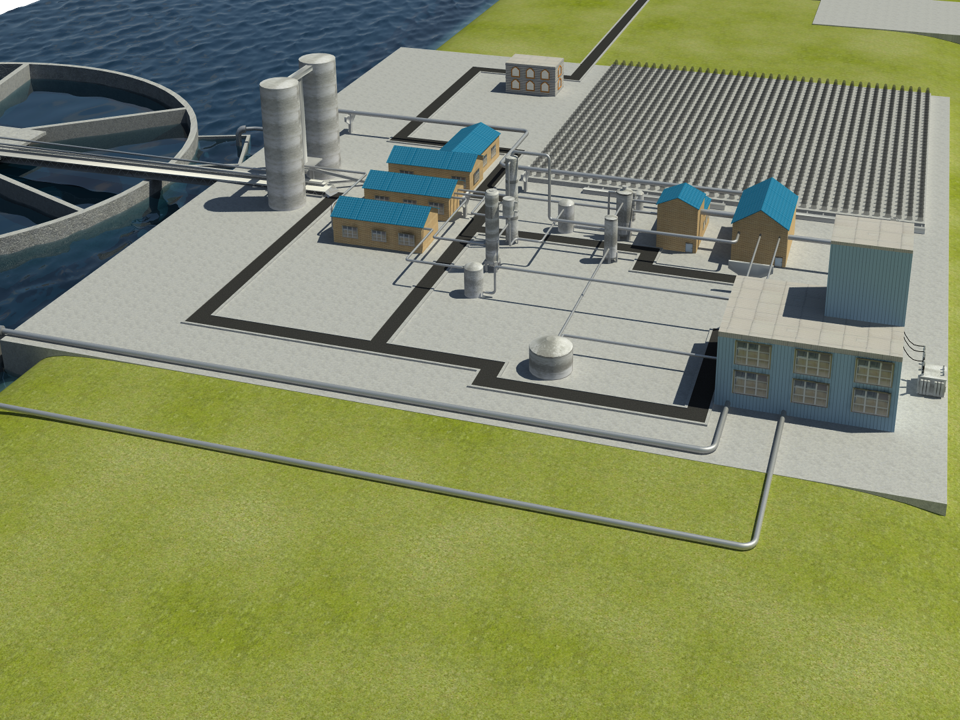

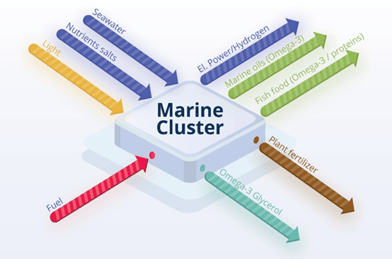

The Marine Cluster project was established and consists of an Oxy-fuel energy plant (power plant), an algae plant for microalgae, and feed product production. The cluster's main products are electric power, hydrogen, marine oils, and marine feed products.

Creating a circular process in Oxy-fuel combustion, the air is replaced with oxygen, and the result is very environmentally friendly combustion with zero emissions of NOX and a hundred percent capture of CO2.

The energy produced in the power plant can be supplied to the power grid or used to produce hydrogen by electrolysis. All resources are used and recycled.

The energy source of the plant (Oxy-fuel steam boiler) comes from wooden pellets. The pellets are burned in a mixture of O2 and recycled CO2. The CO2 gas from the combustion is delivered directly to the photobioreactors (PBR).

For the cultivation process, it is essential to control the concentration of CO2 and O2 towards the most optimal values possible. The closed systems, also called photobioreactors (PBR), operate in a more controlled environment. The combustion gas is mixed to the correct composition and delivered directly to the microalgae. The plant is a system made up of algae cultivation bags in a rack that ensures good agitation in the reactor. As a result, the algae double their weight in one day.

The three main fractions in the algal mass are oil, protein, and carbohydrates. Therefore, relevant alternatives for using the algal mass must be assessed based on market and profitability. The application areas are many: biofuels, health food, cosmetics, feed for the live feed, or supplements in fish and animal feed.

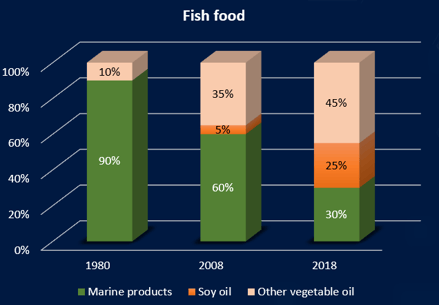

The content of "omega-3" in farmed salmon has been halved during the last ten years due to the lack of marine oils in fish feed. Access to fish oil, which previously made up 100% of the fish feed's oil feed, has become a scarce resource due to deep-sea fishing limitations.

Today, much fish oil is replaced with land-based products such as Soya that do not contain marine fatty acids. As a result, only 30% of fish feed is produced from marine raw materials, reducing the healthy fatty acids (EPA, DHA) in farmed fish accordingly. This unfortunate development can be altered by adding marine raw materials from algae in the fish feed.

Today, much fish oil is replaced with land-based products such as Soya that do not contain marine fatty acids. As a result, only 30% of fish feed is produced from marine raw materials, reducing the healthy fatty acids (EPA, DHA) in farmed fish accordingly. This unfortunate development can be altered by adding marine raw materials from algae in the fish feed.

The unique characteristic of farmed salmon is that its nutrients and nutritional value are affected by the choice of feed ingredients. Therefore, contributions can be increased significantly by selecting feed ingredients containing high levels of these nutrients.

Using all CO2 from the energy plant and the return of O2 from the algae plant to the combustion process will create an environment for producing large quantities of algae, a natural first link in a marine food chain. In addition, it will provide the raw material for high-quality marine oils and feed.

There will be considerable growth in the demand for marine oils "omega-3" as raw material for fish feed in the years ahead. Microalgae has a wide range of applications; feed for fish, feed for animals, and pharmaceuticals, to mention some of them.

With this process, we will continue working towards a green shift, in line with the UN sustainability goals. We work towards Responsible consumption (12), Affordable and clean energy (7), Improve life below water (14), transition in Industry, innovation and infrastructure (9), create Decent work and economic growth (8), and a clear Climate action (13).

Nebb provide total solutions for automation, electrical and information systems to a number of industries world-wide, including process industry, food & pharma, marine, energy, subsea, and PMC.

Our core competence lies within automation, electrical, instrumentation, SCADA, software, and digitalisation.

[fa icon="phone"] +47 66908300

[fa icon="envelope"] sales@nebb.com

[fa icon="envelope"] general@nebb.com

[fa icon="home"] Solbråveien 43, Asker Norway