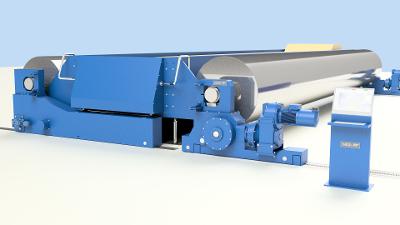

Mechatronic Engineering in applies in the field of mechanical design, electrical design, control systems and computing within several industry segments. Our engineering team is involved in core areas such as the development of new products, as well as in creating solutions for customer projects.

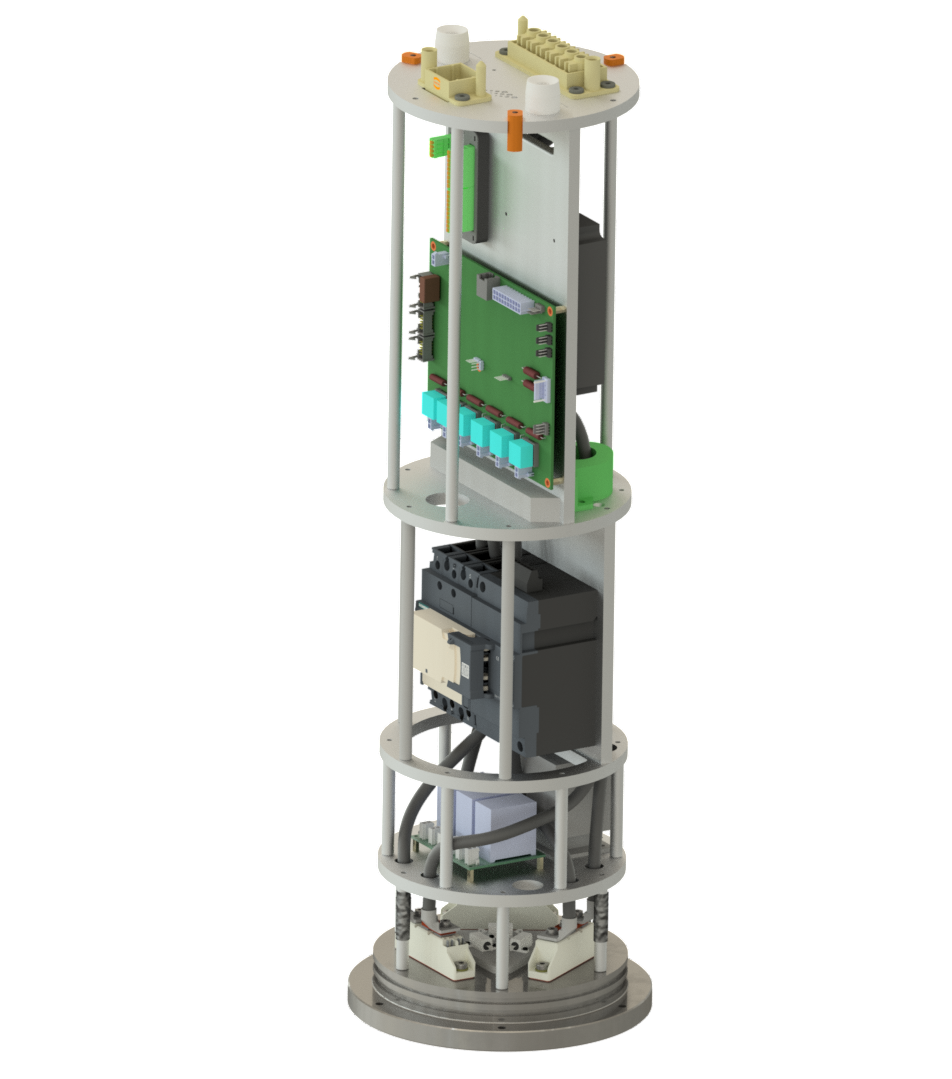

The core activity within Mechatronics in Nebb is the design and realization of multi-disciplinary products, as well as the design of mechanical components and complete machine systems from scratch, with emphasis on optimization.

Nebb employs mechatronic engineering to go from product concept to finished product. We develop a wide range of products for various industries.

This includes but not limited to:

Nebb has experience in selecting the right components for the right design of your product. Nebb develops new products based on our own product portfolio, as well as on customer request.

Autodesk Inventor is our design tool for creation of 3D parts and assemblies, virtually representing the final product. At the same time, it provides validation, checks fits and interference, and performs engineering calculations. This enables our designers and engineers to come up with new products, as well as to optimize the old solutions.

Nebb uses additive manufacturing in the form of 3D printers to make prototype parts early in product development. We also use 3D printing to produce high quality parts for our product assemblies to optimize cost and weight and to make use of the material properties. 3D printed parts are widely used for our subsea products.

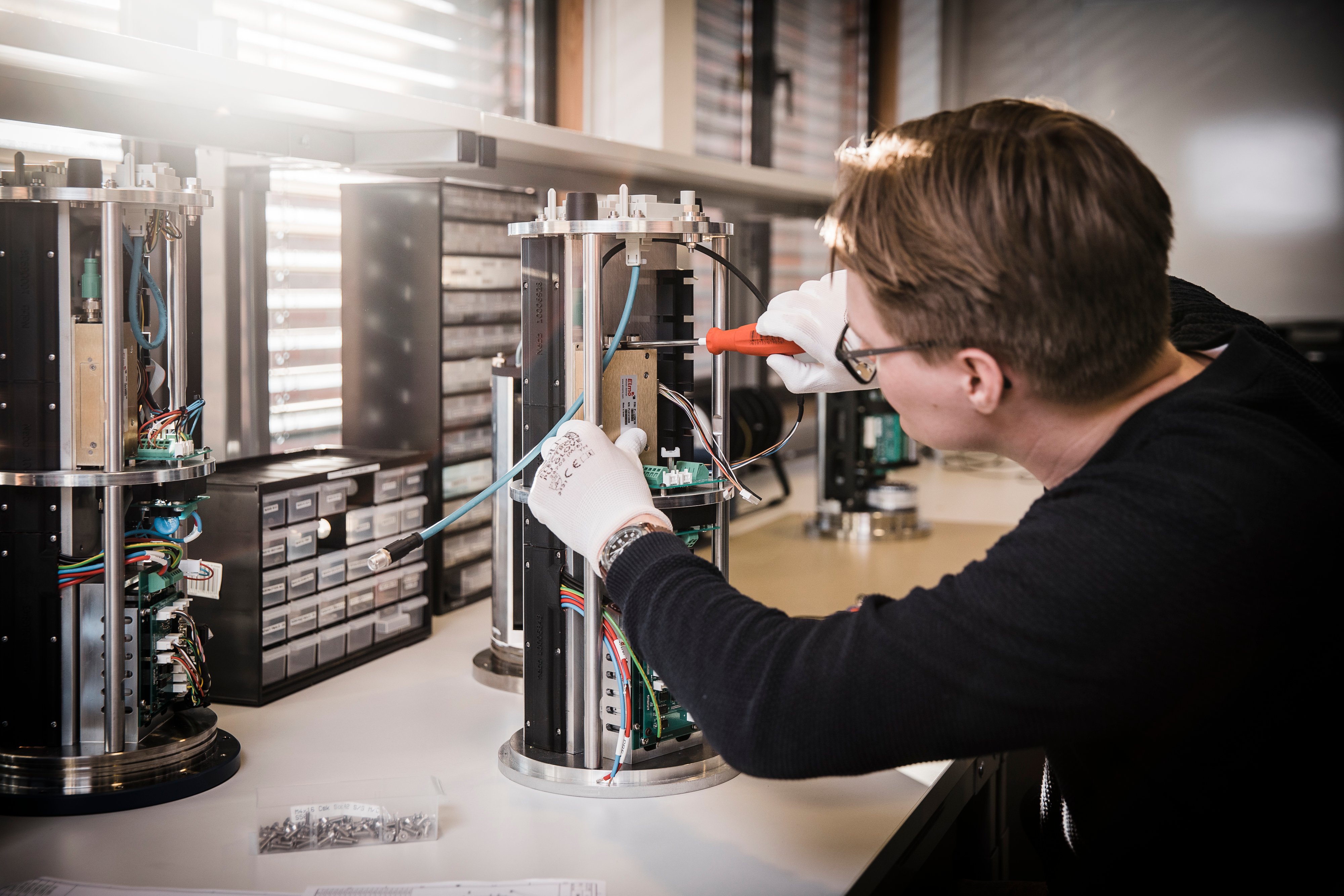

Integration of several commercial off-the-shelf components into products is a way to provide field proven technology into new products. Nebb has a wide experience in identifying and selecting the best available components based on features, application, availability, and other selected criterions.

We perform the necessary production steps and assembly of our products at our location in Asker, Norway. Nebb has the capability to support product manufacturing for a wide range of products.

Nebb performs mechanical design and ordering of manufactured parts for assembly of our products. We are experienced in using a wide variety of materials for different assemblies.

.jpg?width=3009&name=20200421_111020%20(2).jpg)

Nebb provides the necessary PCB design and PCB assembly for our products.

Certification our products and solutions according to the relevant standards are necessary. Nebb has wide experience in qualifying products for subsea use according to API 17F and ISO 13628-6.

Vault data management software helps organize, manage and track product data creation, simulation and documentation files for our engineering and management teams. With Vault, the iterative design processes and revision control are handled while keeping the design process efficient.

CAE is used to simulate the physical performance of a product, in order to improve the product design process and to give solutions to engineering problems. Combining both the CAD and CAE, our engineering and design teams are capable to validate a design, and explore design alternatives before creating a physical prototype. By that, the time for bringing the product to market is significantly decreased.

Keep up-to-date with the latest news, innovation and technology from Nebb. Don't miss out!

Nebb provide total solutions for automation, electrical and information systems to a number of industries world-wide, including process industry, food & pharma, marine, energy, subsea, and PMC.

Our core competence lies within automation, electrical, instrumentation, SCADA, software, and digitalisation.

[fa icon="phone"] +47 66908300

[fa icon="envelope"] sales@nebb.com

[fa icon="envelope"] general@nebb.com

[fa icon="home"] Solbråveien 43, Asker Norway