There are three main* competing technologies for CCS: post-combustion, pre-combustion and oxyfuel. Different groups work with and favour the different technologies, so there is no consensus on which technology is the right one for the future.

In post-combustion, the CO2 is stripped out of a gas stream by physical or chemical absorption. Examples of post-combustion technologies are the amine separation and chilled ammonia methods. Some of the advantages of these technologies are that they can be fitted to existing installations, and they can handle CO2-containing gas streams from industrial sources. Some of the disadvantages are the high cost and physical size of the installations, and the risk of chemical emissions (amines) that are potentially harmful to the environment.

In pre-combustion, the fuel is gasified and shifted to a mixture of mainly CO2 and H2. The CO2 is stripped out under high pressure, and the H2 is used in turbine cycles. Some of the advantages of this technology are that the CO2 is stripped out under high pressure, which makes the process efficient, and that potentially, the overall process could be relatively efficiencient. Some of the disadvantages are high investment costs, complex plant with low up-time, and that an H2 turbine needs to be developed.

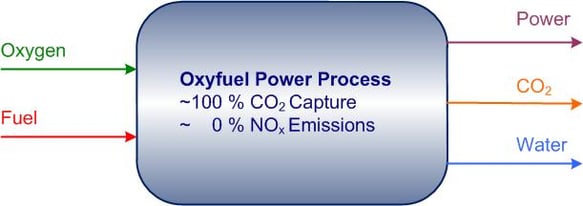

In oxyfuel technology, the first step is to separate the oxygen from the air. The fuel is then combusted in a mixture of oxygen and recycled flue gas. The flue gas consists mainly of CO2 and H2O, so the CO2 can be separated by condensing out the water. Some of the main advantages of the process are the ability to capture up to 100% of the CO2, and that there are no emissions into the atmosphere (no NOx). Some of the main disadvantages are that a turbine needs to be developed for high-efficiency gas power plants and that air separation is quite energy demanding.

Nebb believes that oxyfuel will be the dominating technology for power production in the future, due to the powerful advantages mentioned; up to 100% CO2 capture, no chemicals and no NOx emissions. In addition, there is the potential for a future reduction in energy consumption during air separation, which will favour the oxyfuel technology. The investment costs and installation sizes will, from our perspective, also favour the oxyfuel technology.

*It should be noted that in addition to the three main technologies, there are several research programs ongoing to develop and evaluate alternative technologies for CCS. Examples of these technologies are chemical looping combustion, membrane separation and cryogenic separation.

Read more:

Oxyfuel Development

Nebb provide total solutions for automation, electrical and information systems to a number of industries world-wide, including process industry, food & pharma, marine, energy, subsea, and PMC.

Our core competence lies within automation, electrical, instrumentation, SCADA, software, and digitalisation.

[fa icon="phone"] +47 66908300

[fa icon="envelope"] sales@nebb.com

[fa icon="envelope"] general@nebb.com

[fa icon="home"] Solbråveien 43, Asker Norway