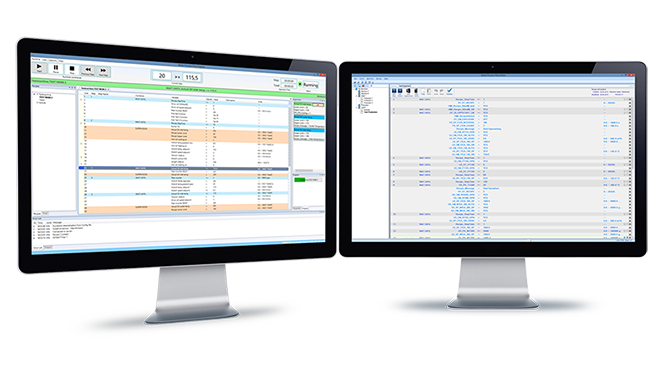

Integrated with industry leading SCADA system solutions the ProcessPilot reduces downtime, improves efficiency and increases Overall Equipment Effectiveness (OEE).

The ProcessPilot works well in a dynamic, interconnected workplace. You can create and edit recipes at your convenience. Time and effort spent on unplanned interventions are significantly reduced.

Detection and early elimination of faulty operations help to prevent human error. Since quality measures are constantly performed, any deviations are registered immediately and counter-measures can be introduced.

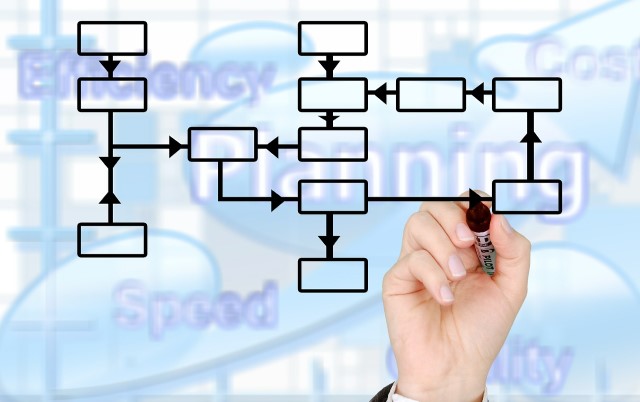

Streamline production performance by providing full Repeatability and Reproducibility (R&R) by best operator. Production managers can easily set the optimal process steps and replicate accurate systematic operations performed by operators.

The ProcessPilot controls the process in a manner that is both accurate and repeatable. By the predictability of the processing, production planning can be accomplished with greater accuracy and processing time substantially shortened.

Deployed with industry leading SCADA system solutions the ProcessPilot ensures system integration with data from internal information systems.

Reporting modules such as production reports and comparison reports are available as an additional feature. You can display analyzer reports in a dashboard for a more interactive user experience.

Go to ProcessPilot.net for a dedicated site to this platform. Or contact us for more information or a personal demonstration.

Nebb provide total solutions for automation, electrical and information systems to a number of industries world-wide, including process industry, food & pharma, marine, energy, subsea, and PMC.

Our core competence lies within automation, electrical, instrumentation, SCADA, software, and digitalisation.

[fa icon="phone"] +47 66908300

[fa icon="envelope"] sales@nebb.com

[fa icon="envelope"] general@nebb.com

[fa icon="home"] Solbråveien 43, Asker Norway