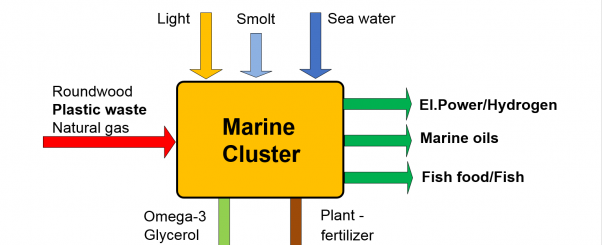

Focusing on sustainable industrial production, Nebb has developed an industry cluster that combines several industry processes to achieve zero emission production. Centrally here is oxyfuel energy production based on solid fuels in combination with by-products from other industries which is very valuable for achieving good profitability and sustainable development.

Focusing on sustainable industrial production, Nebb has developed an industry cluster that combines several industry processes to achieve zero emission production. Centrally here is oxyfuel energy production based on solid fuels in combination with by-products from other industries which is very valuable for achieving good profitability and sustainable development.

The Marine Cluster has been developed through several years and has its origins in oxyfuel technology designed for zero-emission gas power plants. However, due to high gas prices, Nebb was looking for alternative energy sources. Wood and plastic waste are available and possible to utilize for energy production and if you do it properly, you will get almost zero emissions.

A key advantage of the Marine Cluster is the idea to combine oxyfuel energy production with CO2 capture. It is a combination of an oxyfuel power plant, an algae cultivation plant, a fodder plant, and a fish farm with fish processing.

Production of microalgae for extracting marine oils (Omega 3) and other products is also an emerging industry. Accelerated algae growth rate can be achieved by adding pure CO2 from the oxyfuel process. Thus, it seems that the combination of oxyfuel power production and algae production is a perfect match. The oxygen from the algae production can be used in the oxyfuel process, and the collected CO2 can be used to speed up algae growth.

To find out more go to Marine Cluster and read about the utilization of waste materials and by-products from the processes in the various production facilities, and the zero hazardous emission to water, air or earth.